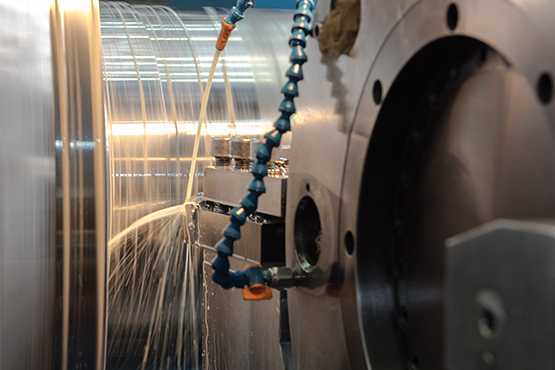

Machining

All the required machining processes can be carried out according to customer’s specific requirements in the mechanical processing shop.

We can performed the following machining operations:

Turning

Drilling

Boring

Grinding

Our machining shop is equipped with:

- 33 Horizontal Lathes (Conventional and CNC) with capacity: from 50mm to 4000mm diameter, up to 28m long and up to 140ton weight

- 12 Vertical Lathes (Conventional and CNC) with capacity: up to 5600mm diameter, up to 2500mm high and up to 80ton weight

- 13 Milling & Drilling Centers (Conventional and CNC) with capacity: up to 10.000 x 4.000 x 1.900mm and up to ~150ton weight

- 8 Deep Drilling Centers (Conventional and CNC) with capacity: from 44mm to 1000mm diameter, up to 16.000mm long and up to 55ton weight

Our machines, conventional and CNC, are prepared for high-performance rough machining and precise final machining of forged products, ensuring the highest level of quality.

We develop process automation, which guarantees a high level of reliability in production.

Our production line for machining monolithic crankshafts for high-power four-stroke engines is one of the most modern in Europe.

In 2019, we expanded our offer to include the production of a comprehensive line of ship shafts up to 24 m long.

In addition to the range of turning, milling, drilling, we also perform the assembly (shrink connection) of bronze sleeves purchased only from European companies. Final operations, such as coating, are performed in cooperation with specialized companies. We apply PHILLYCLAD 1775/620 and Celloflex M coatings.

We can make electric generator shafts and turbine rotors together with honing and magnetic testing of holes.

The production line includes milling machines, special CNC turning-milling machines, CNC grinding machines, a device for magnetic measurement and control of geometric parameters.